Unique, economically designed steel pipe highly resistant to earthquakes.

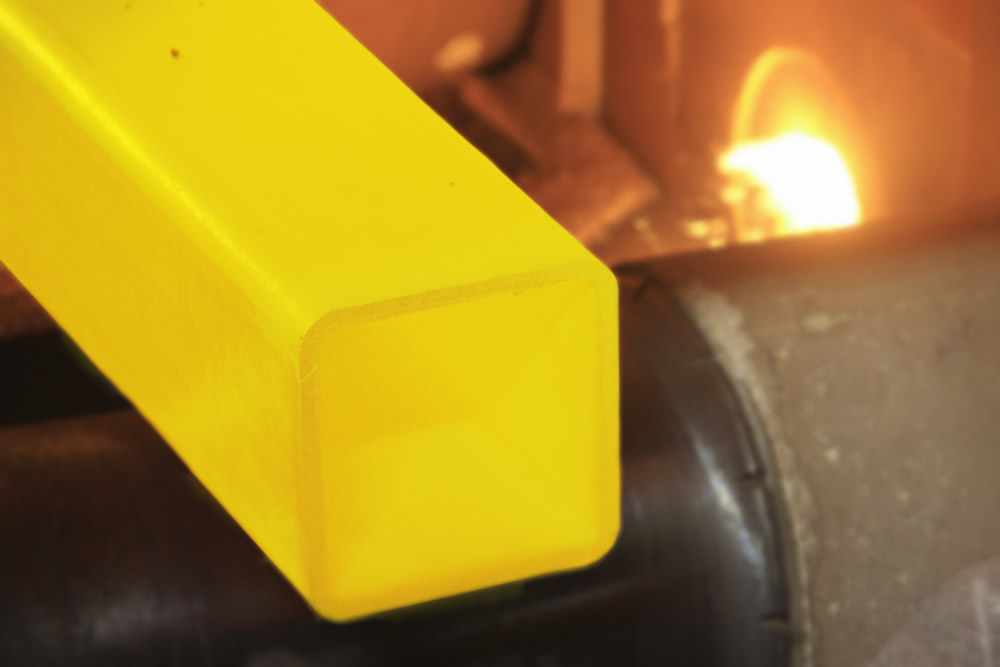

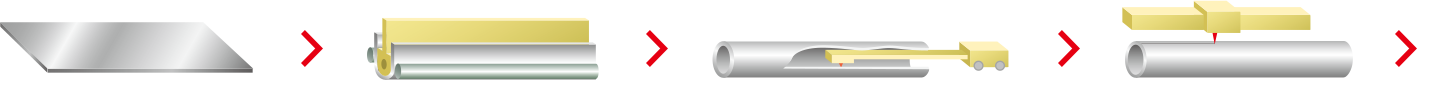

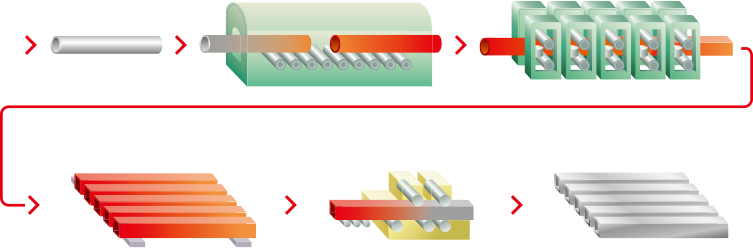

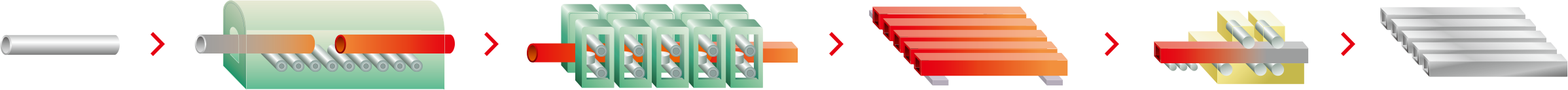

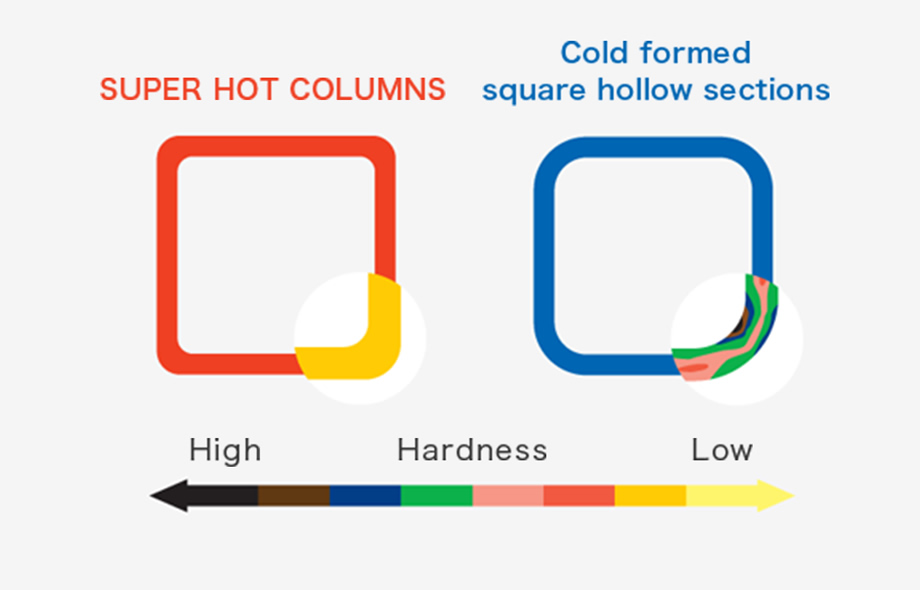

Hot finished square hollow sections are Structural steel pipes highly resistant to earthquakes and with the inherent toughness of steel obtained by hot finished. Through technical collaboration with British Steel (the current Tata Steel) in the UK on hot finished and our proprietary technology, NSP developed a unique Hot finished square hollow section named “SUPER HOT COLUMN” and succeeded in putting it into mass production. SUPER HOT COLUMN in large sizes up to 800 mm x 800 mm in side length and 70 mm in thickness is certified according to EN10210. NSP also manufactures products conforming to ASTM A501/A501M. The quality of these products is highly thought of in the global market.