Easy to manufacture at low cost while meeting the needs for a short delivery time, etc.

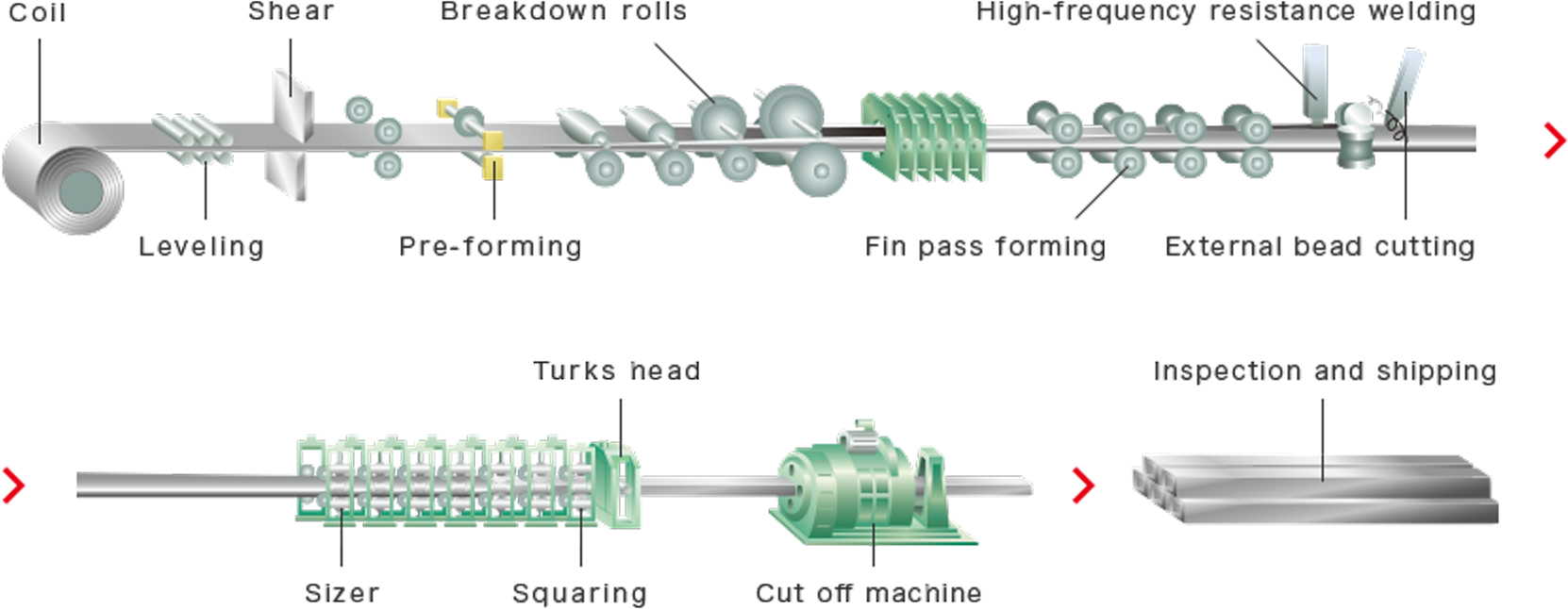

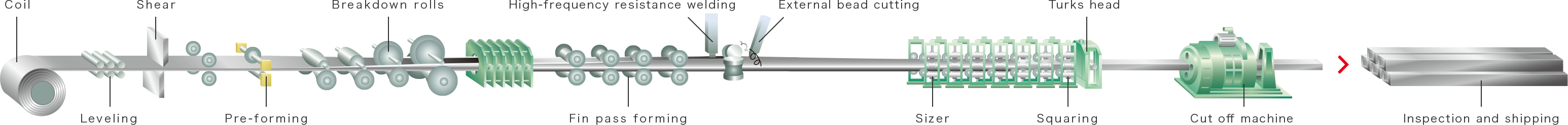

Cold roll formed square hollow sections for building structures are manufactured using the roll forming method. Coil continuously bent by the forming rolls undergoes electric-resistance welding, and it is continuously formed into the circular hollow sections and then into the square hollow sections. NSP has one of the world’s largest manufacturing facilities to produce 26-inch electric resistance welded pipes with roll forming process.